Soller, D.R. and M.C. Reheis, 2004, Surficial Materials In The Conterminous United States. U.S. Geological Survey Open-File Report OFR-03-275

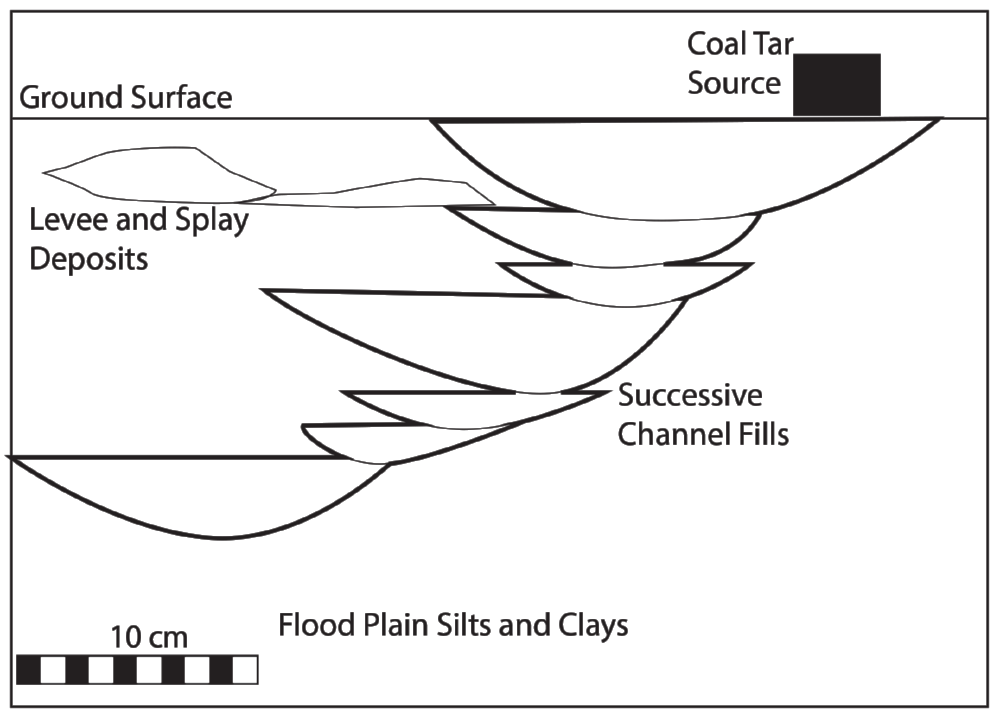

FIGURE 1: Because the competent bedrock in more than half of the U.S. landmass is covered with fluvial, glacial or coastal/ estuarine sediments of various ages, the results of these experiments have widespread applications.

Contaminants variably migrate through and around fine- and coarse-grained layers that define a site’s “subsurface plumbing.” Through these experiments, our environmental scientists demonstrated that it is not only possible to predict what this plumbing looks like with very little new exploration but also how contamination will migrate and accumulate in those conditions.

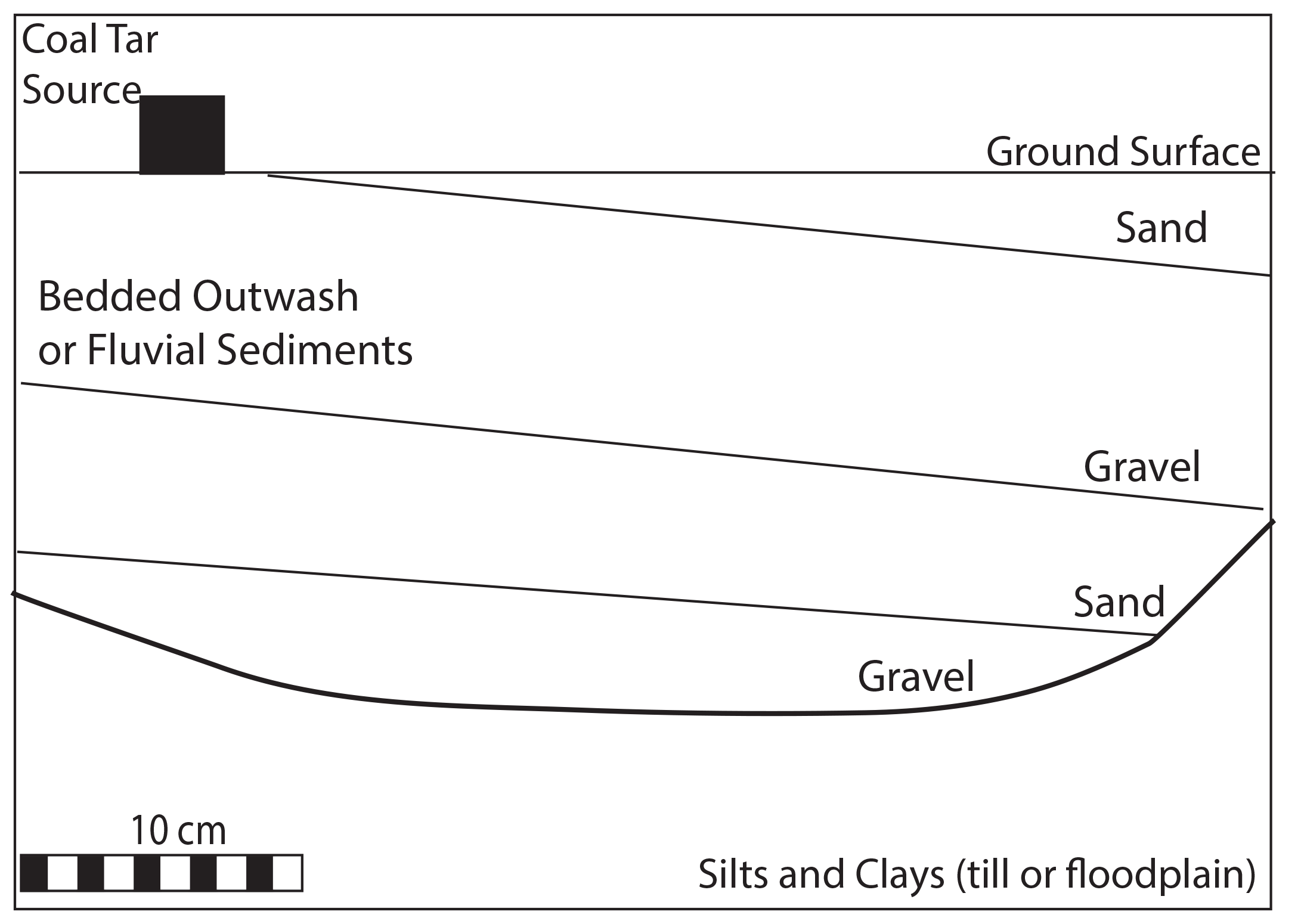

Using physical models, our environmental scientists assessed NAPL migration through a saturated subsurface in three common stratigraphic scenarios:

- Sands over clay — which is comparable to glaciofluvial outwash over till;

- Cross-bedded sands — which is comparable to point-bar deposits in rivers; and

- Sand lenses encapsulated within clays — which is comparable to the “cut-and-fill” stratigraphy common in river valley sediments.

These scenarios were selected because they represent commonly encountered stratigraphy in fluvial, glacial and coastal/estuarine settings.

In fact, the competent bedrock in more than half of the U.S. landmass is covered with fluvial, glacial or coastal/estuarine sediments of various ages.

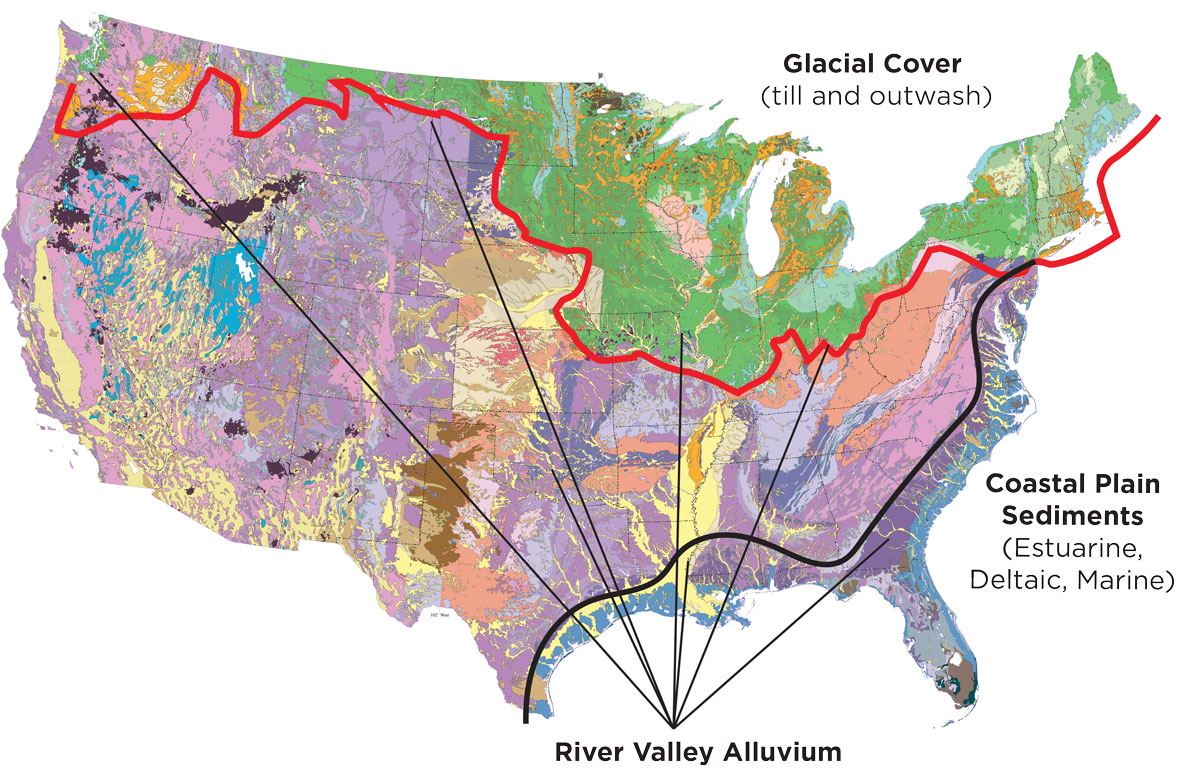

After using time-lapse photography to record the behavior and migration of the NAPL into the porous “aquifer” media, the scientists developed a summary plot illustrating the migration. By comparing the resulting plume geometries, scientists ascertained the relative impact of geology on NAPL migration.

FIGURE 2: Two stratigraphic scenarios were investigated: Dipping sedimentary beds (left) and overlapping coarse lenses of sediment encapsulated in finer materials (right)

LESSONS LEARNED

These bench-scale experiments demonstrate that the arrangement of fine-and coarse-grained layers of sediment that comprise the stratigraphy does indeed define the “subsurface plumbing” through which contaminants move. They show that trends in grain size directly influence both the NAPL migration pathways and movement rates. They also suggest that, under relatively stable groundwater conditions, an NAPL plume head selects the largest available pore-neck as its preferred pathway. As a result, medium to coarse sand, despite being very porous, may still act as a barrier to NAPL migration if it is overlaid with medium to coarse gravel. This finding has important implications for vertical plume migration, given the cyclical nature of vertical grainsize trends in the majority of depositional systems.

FIGURE 3: Environmental scientists used time-lapse photography to plot the path coal tar residuals take through the fine- and coarse-grained layers of “subsurface plumbing.”

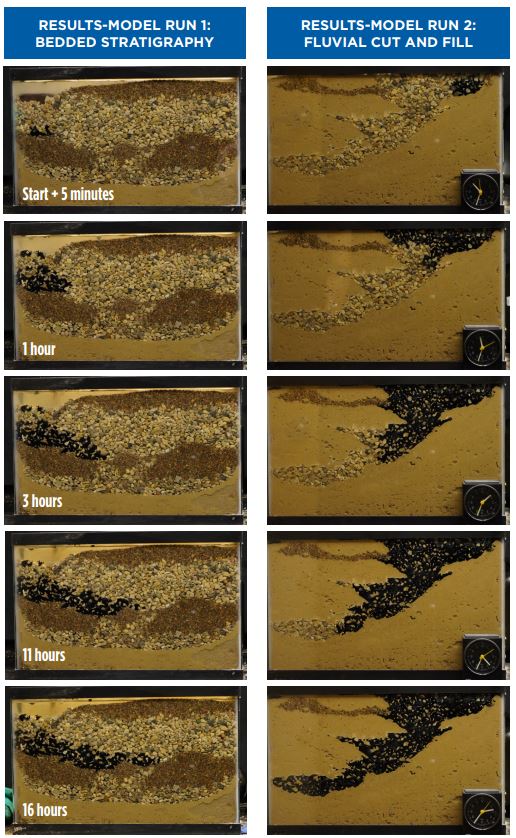

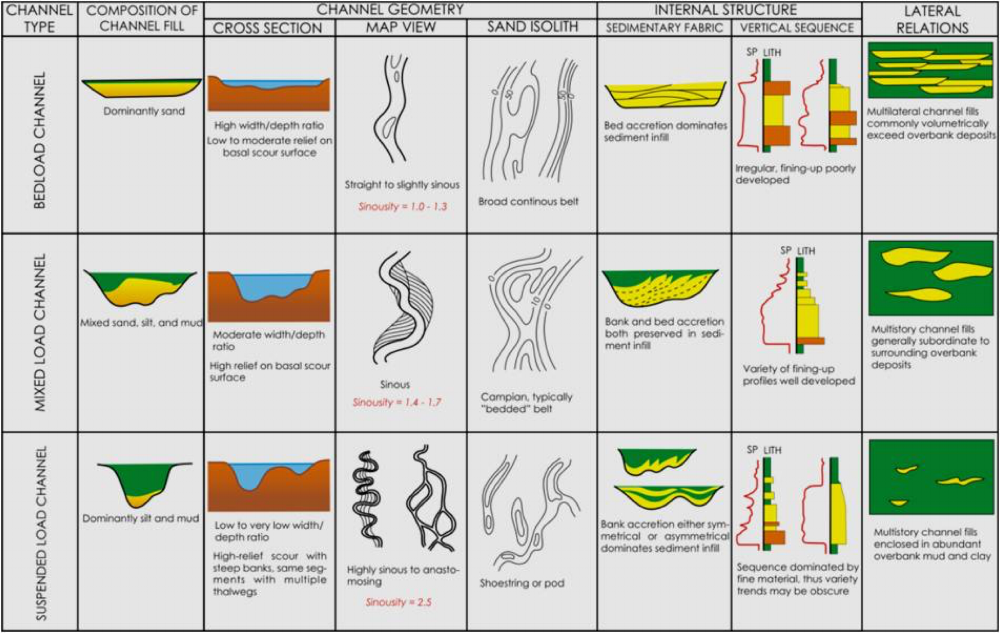

The lessons learned from the bench-scale experiments can be used to create better Conceptual Site Models (CSMs). Leveraging these basic lessons, however, depends on a remediation team’s ability to use the stratigraphic clues in their data to recognize the position of a given MGP site relative to the overall stratigraphy. A technique such as Environmental Sequence Stratigraphy, for example, is ideally suited for this task because it uses vertical grain-size trends, knowledge of depositional settings and reasonable modern equivalents to establish a CSM that is predictive in nature with testable hypotheses of grain-size distributions (or lithofacies) between and beyond data points. What’s more, NAPL behavior, migration and plume geometry can also be predicted within this geologic context.

All are key to reduced uncertainty and improved understanding of project costs, risks and the pathways to closure

FIGURE 4: By studying fluvial geomorphology and its relationship to the subsurface architecture and vertical grain-size trends, environmental scientists are able to compile and tabulate the large datasets needed to determine sediment body width-to-thickness ratios, typical depositional dips and other empirical and fundamental geometric relationships.