System operators are increasingly exploring opportunities to update or replace existing black start assets with battery storage technology. Before implementing a battery energy storage system (BESS) to support black start capabilities, operators should take into account both the benefits and some BESS-specific considerations.

Black start is the process of restoring an electric power station or a part of an electric grid to operation without relying on the external electric power transmission network to recover from a total or partial shutdown. The North American Electric Reliability Corp. (NERC) requires regional transmission organizations (RTOs) to maintain at least two strategic black start facilities per zone to provide faster restoration and recovery of the bulk power system in the event of a widespread outage or blackout.

To provide a black start, some power stations have small diesel generators or gas generators that can be used to start larger generators (of several megawatts capacity). These, in turn, can be used to start the main power station generators. Some of these black start assets are beginning to reach the end of their life span. To maintain system reliability and recoverability requirements, some RTOs are issuing requests for proposals (RFPs) or implementing new tariffs and rate structures to incentivize black start capabilities at generation facilities.

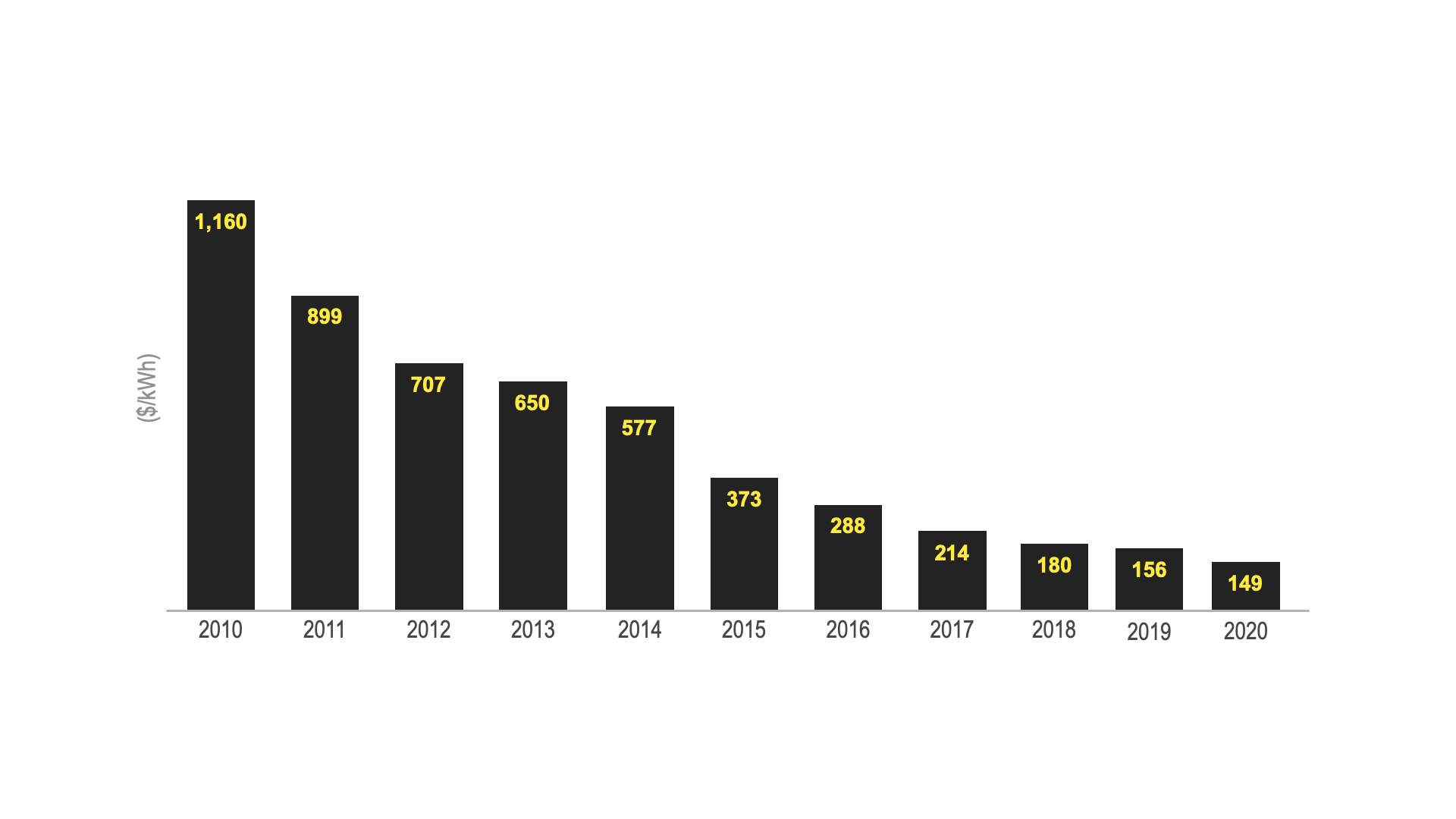

At the same time, falling prices for lithium-ion (Li-ion) battery technology have made BESS projects much more economically feasible for a variety of grid functions, including black start. Li-ion costs have declined by more than 85% since 2010 and are forecasted to fall an additional 65% during the next decade, as shown in Figure 1.

Figure 1: Li-ion battery pricing outlook.

In addition to capital cost, a BESS typically may have significantly lower costs for operations and maintenance over the life of the system as compared to traditional fossil-fueled generators. Furthermore, such systems, depending on size and design, could be used to support other grid ancillary services, providing a potential additional revenue stream to the owner.

A BESS also provides asset owners and stakeholders significant environmental benefits. As a zero-emission generation source, utilities do not need to modify existing air permits to add a BESS, and the overall footprint is typically less than a diesel or gas-fueled generator.

Exploring the Key Considerations

Black starting a large combustion turbine is a complex undertaking regardless of the power source. Retrofitting existing plants using static starting systems, such as load commutated inverters (LCI), to start the turbine presents challenges related to harmonics and short circuit current. Original equipment manufacturers (OEM) define a minimum amount of short circuit current needed for the static starting system to work properly. Diesel generator sets typically are supplied with synchronous generators that have both rotational mass and relative high short circuit current.

For example, one diesel generator could have six times its full load amps in short circuit current while a BESS inverter has 1.2 times. Without the required short circuit current, the harmonics produced by the static starting systems can be significant. They can even impair the functionality of the starting system and other components in the electrical system. Over the last few years, harmonic filtering has shown promise as an effective mitigation strategy and as a possible solution to the short circuit challenge.

The size and use of the BESS are other key considerations. Traditional diesel backup generators typically have enough fuel storage to support 24 hours of continuous operation. If the need surpasses the 24-hour period, then the owner simply has to refill the tank with more fuel. With a battery, you have a fixed amount of energy available to start the turbine, and assuming the system is black, no easy way to recharge the battery. Therefore, as you size your BESS, the size should be based on the ability to provide critical auxiliaries between the time the power goes out and when a turbine start has been requested, plus a certain number of starts for the combustion turbine.

Sizing also must consider how the BESS will be used and maintained. Some Li-ion battery chemistries degrade faster if they are required to maintain a consistently high state of charge (SOC). Depending on use and type of battery, asset owners will likely need to either select a high SOC-friendly chemistry, oversize the battery, or operate the battery in a way that maintains a 50% average SOC.

Understanding the Market Landscape

A recently installed BESS provides black start capabilities for a 200-megawatt simple-cycle power station located in the Southeastern U.S. System tests show that a BESS is a technically viable alternative for large combustion turbine black start applications. The project also shows the BESS to be an economically viable alternative to traditional diesel generators.

System features include a relatively small BESS, designed specifically to support up to two generator restarts. The system also makes use of the plant’s existing emergency diesel generator to provide backup power for the plant auxiliaries between plant blackout and turbine startup. To resolve the issues associated with low short circuit current without dramatically increasing the number of inverters, a large harmonic filter was incorporated into the design.

Now that the black start with BESS concept has been proved, interest is growing for use in a number of plants across the country. Another BESS black start system is close to completion for a separate Southeastern utility and more are expected across the country in the coming year. As the power industry continues to integrate more renewables, reliability in power generation will be a key component in a successful transition — and BESS black start could be a key part of this change.

The outlook for Li-ion battery technology is promising. The technology of choice for utility-scale energy storage configurations, further growth for Li-ion batteries will depend on how manufacturers and the utility industry address safety challenges.