As a focus on environmental, social and governance (ESG) scores continues to grow, many industries are seeking increased opportunity for sustainable and low carbon initiatives. One major player that can help reduce carbon footprint comes in the form of hydrogen — particularly, when it is produced through methods that either capture or do not emit carbon dioxide.

Traditional hydrogen production methods used today can be carbon-intensive, driving heightened awareness of decarbonization methods throughout the hydrogen production process. Hydrogen offers several benefits in the ever-changing power and industrial markets as an alternative, clean, reliable fuel source when produced using technologies purposed for decarbonization. Budding market opportunities like rising transportation penetration, elevated production of hydrogen-intensive renewable fuels, emerging long-term energy storage capabilities, and growing integrated or hybrid energy systems increase the need for hydrogen production.

Despite most hydrogen production utilizing steam methane reforming (SMR) at this time, hydrogen can be created many ways, using a variety of inputs or sources, which each have a different impact on the environment. Production methods can include gasification plants, SMR, pyrolysis and electrolysis. The inputs that go into production vary from oil, coal or biomass to natural gas or methane, and finally, water with renewable power or nuclear input.

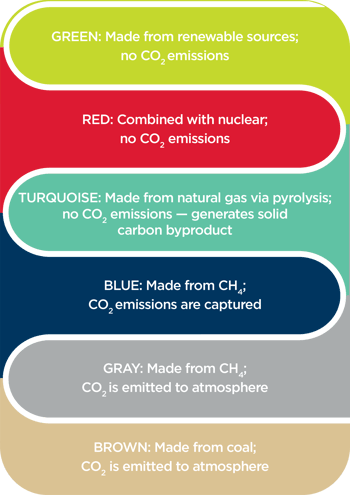

This can be more easily shown and understood by analyzing the “hydrogen rainbow,” which is divided into color categories based on energy sources, production processes and carbon dioxide emissions:

Figure 1: Industry is adopting a "color rainbow" to easily distinguish the sources of hydrogen the its renewable credentials.

- Green — In the green category, hydrogen is made from renewable sources. Electrolyzers are paired with renewable assets that are frequently curtailed, creating hydrogen by splitting the water into hydrogen and oxygen. This category emits zero carbon dioxide emissions. Once the hydrogen is collected from the electrolyzer, it can be used to power homes, cars, planes, ships and factories, and can also be safely stored for future applications.

- Red — Also referred to as pink, this category features hydrogen when it’s produced with nuclear power sources. Like green, it is also generated through electrolysis. There are no carbon dioxide emissions associated with this process.

- Turquoise — In this grouping, hydrogen is made via pyrolysis using natural gas. There are no carbon dioxide emissions using this method, but it does produce a solid carbon byproduct that must be handled.

- Blue — In the blue category, hydrogen is made from methane using SMR. The carbon dioxide emissions that are generated are trapped through carbon capture.

- Gray — This grouping is similar to blue, except the carbon dioxide emissions are emitted into the atmosphere and are not captured. By adding carbon capture technology, this category can be shifted from gray to blue.

- Brown — For the brown category, coal is used to produce hydrogen through gasification. The carbon dioxide emissions are released into the atmosphere. This is not an ideal solution when discussing how to use hydrogen to decarbonize.

While the colors of the hydrogen rainbow aren’t officially standardized across the industry yet, sustainable and low-carbon energy initiatives are in development and being implemented across the globe, each targeting carbon emission reductions. The viability of hydrogen as a high-energy-capacity storage medium with no-carbon potential makes investment in the hydrogen rainbow attractive in this context. Trends indicate continued growth in hydrogen demand as new markets develop and existing user demand expands, requiring investment in a sustainable transition to a reduced-carbon future.

As trends toward decarbonization and renewable generation gain steam, interest in hydrogen has reemerged as a potentially key technology in the evolution of the power industry.