Many important infrastructure systems contribute to a successful, operational airport. Terminals, road networks and security — just to name a few — work in tandem to provide excellent passenger experiences, maintain complex schedules, and keep travelers and employees of airlines and airports safe.

However, one critical component of seamless airport operations often gets overlooked: an airport’s pavement infrastructure. Understanding what it takes to keep airside pavements in excellent condition is an essential part of maintaining uninterrupted operations.

FAA and Pavement

Typically, a large airport will have several million acres of pavements, which is a lot of infrastructure to maintain. Most large airports face the challenge of maintaining the pavements in good condition without impeding airside operations. In many instances, by the time one pavement area undergoes rehabilitation and repair, another area will be ready for maintenance or even reconstruction. Making matters worse, these sections are often the most frequently used pavement areas — ones subjected to large aircraft movement, often with several hundred passengers on board.

The Federal Aviation Administration (FAA) has long supported the use of an Airfield Pavement Management System (APMS) to provide each airport within the National Plan of Integrated Airport Systems information on the condition of their pavement systems. Such a plan provides each airport with an engineering-based evaluation to develop budgets, maintenance types and capital improvement development for pavement maintenance, rehabilitation and reconstruction projects.

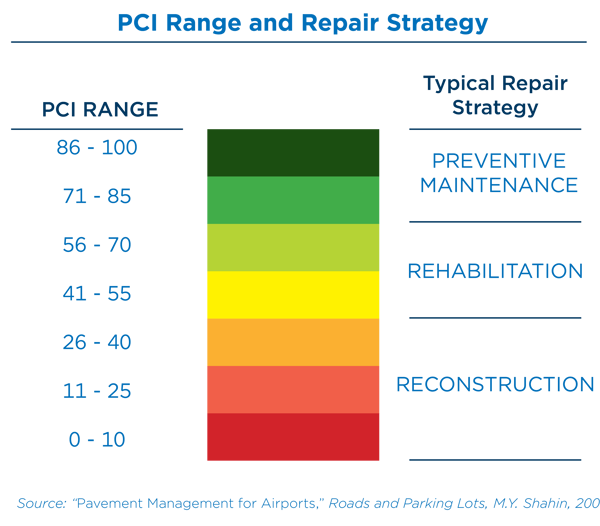

A typical APMS project starts with a records review followed by a visual pavement evaluation. The evaluation is usually performed by a team of qualified pavement engineers or technicians who walk the pavement to record distress and other important pavement information. This information is then processed in software to develop the pavement condition rating as shown on the Pavement Condition Index (PCI) — a 1 to 100 scale range where 100 represents the highest rating/best condition and 1 represents the lowest rating/worst condition. Following a successful PCI inspection, the airport owner will be able to easily identify which pavement areas are in good condition and which ones need attention. The program can also be used to predict the condition of pavements for the next five to 10 years.

While pavement might look sound, visual inspections don’t provide insight into what is going on underneath. Fortunately, there are ways to gain that knowledge.

Destructive and Nondestructive Testing

As part of an APMS project, airports may perform either destructive or nondestructive testing to get a more comprehensive look at the structural integrity of a pavement section.

In destructive testing, a core sample is usually extracted from the pavement then sent to a lab for testing and analysis. The results provide a more detailed report on the structural condition of the pavement.

In nondestructive testing, equipment such as a heavy deflectometer is brought on-site to model similar aircraft wheel movement patterns of heavy or fully loaded aircraft in use, further testing pavement strengths. A deflectometer drops heavy weights gently onto the pavement, then measures the deflection of the surface. Sensors attached to the pavement measure any deflection that occurs based on the force exerted on the pavement. This data then provides a profile of the overall pavement condition.

Destructive testing offers an excellent source of information but usually damages the tested pavement and is disruptive to airport operations. Nondestructive testing, however, offers a good level of information without destroying pavement structures, offering insight with less airside operational impact.

Added Benefits

It is common that airport stakeholders — such as airport operators and airlines — will want to maintain seamless operation as much as possible. Implementing an APMS is the first step for any airport to start planning for pavement rehabilitation and maintenance without impeding airside operations.

An APMS implementation can provide an airport with a single document containing the following information to be used on future capital projects:

- Pavement structure information — Includes all surface- and base-layer thicknesses as well as soil conditions and drainage features information. A document containing this data can be used for any as-built pavement structure information.

- Maintenance history — This provides the airport with a documented list of any maintenance performed on the pavement and can be used as justification to perform further paving rehabilitation and reconstruction projects.

- Pavement Condition Index — Provides ratings that can also be used to justify Airport Improvement Program grant-eligible projects.

- Prediction of budget and future pavement condition — A complete plan provides the capability to create a budget for future maintenance activities and a condition index if no work is performed.

- Project prioritization — Provides information such as pavement condition, traffic usage and structural information that can assist airport leaders in making informed decisions on the prioritization of pavement rehabilitation and reconstruction projects.

Los Angeles World Airports was able to evaluate more than 100 million square feet of landside and airside pavements with minimal disruption to operations.