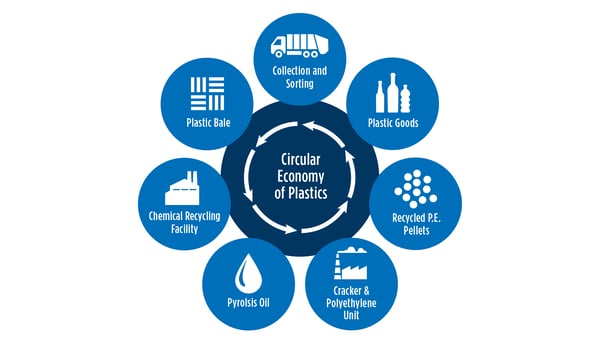

Demand and desire for more recycled content in useable goods continues to rise. An idealized circular economy of plastics implies that plastic molecules are recycled back into plastic goods directly: For example, mixed plastics are collected, processed in a recycling facility, fed to a cracker and polyethylene (PE) unit, turned into plastic pellets again, used to produce goods, then collected and the goods are recycled to start the process over. A similar cycle could be shown for polystyrene, PET or other recyclables.

The reality, including tracking molecules and accounting for recycled content, is actually more complex and difficult to manage. But with an ultimate goal of increased sustainability in the industry, molecular management is needed.

The reality, including tracking molecules and accounting for recycled content, is actually more complex and difficult to manage. But with an ultimate goal of increased sustainability in the industry, molecular management is needed.

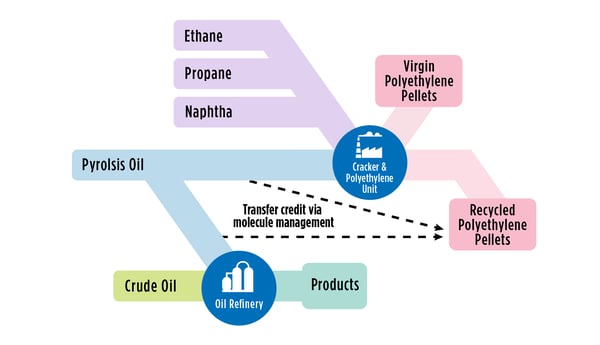

Let's utilize mixed plastics recycling as the basis of our discussion. Currently, the amount of pyrolysis oil being produced from recycled plastic chemical processing is relatively small in comparison to the amount of feedstock needed to supply a typical cracker and PE unit. This pyrolysis oil, after additional treatment, could be fed to certain liquids crackers across the world. However, since feedstock and product streams all run through the same cracker, attempting to track which plastic pellets are made from recycled pyrolysis oil versus the normal hydrocarbon feed stream would be difficult.

As a further complication, the shale boom in the U.S. led to significant investment and infrastructure for creation of plastic PE from ethane. Pyrolysis oil is significantly different from ethane, and not all U.S. crackers can process this, another stumbling block in the circular economy, at least for domestic producers.

Over the past few months, nagging questions have lingered: How can plastics producers claim a specific plastic bottle, for example, is made from recycled content when all of the feed and product streams are mixed together and individual molecules that came from recycled pyrolysis oil aren’t tracked? How do we know what percentage of that bottle, if any, actually came from recycled plastic products? Information from the International Sustainability & Carbon Certification website helps shed some light. This organization provides a solution via molecular management in two different forms.

Utilizing Mass Balance Accounting

With this method, if 10% of a cracker and PE facility feed is recycled-content pyrolysis oil, and the other 90% comes from first-time-use hydrocarbons, the facility can market 10% of its product as recycled PE, regardless of where each molecule ends up. There is not a need to physically segregate or track the molecules that came from a true recycled source, because on average, the percentage of product from recycled content remains consistent.

Exchanging Trading Certificates

Using trading certificates, a U.S. ethane-based cracker and PE facility, even one that cannot functionally operate on pyrolysis oil, could market its PE product as containing recycled content by purchasing a credit or certificate from another entity — as an example, a refiner — that blended the recycled pyrolysis oil into its feed stream. In doing so, the refiner would no longer be able to claim the renewable content in its products; that designation would go to the PE producer instead.

There are indications that regulations may be put in place to require producers to increase the amount of recycled content in their finished plastic products — by introducing an obligation-based program — similar to the Renewable Fuel Standard program for refiners. We are keeping an eye on this, and are ready to support the industry through any upcoming changes.

There are indications that regulations may be put in place to require producers to increase the amount of recycled content in their finished plastic products — by introducing an obligation-based program — similar to the Renewable Fuel Standard program for refiners. We are keeping an eye on this, and are ready to support the industry through any upcoming changes.

The chemical industry is focused on creating long-term, sustainable solutions to maximize the benefits of plastics while reducing their environmental impact. Utilizing molecule management practices furthers the implementation of the circular economy of plastics.