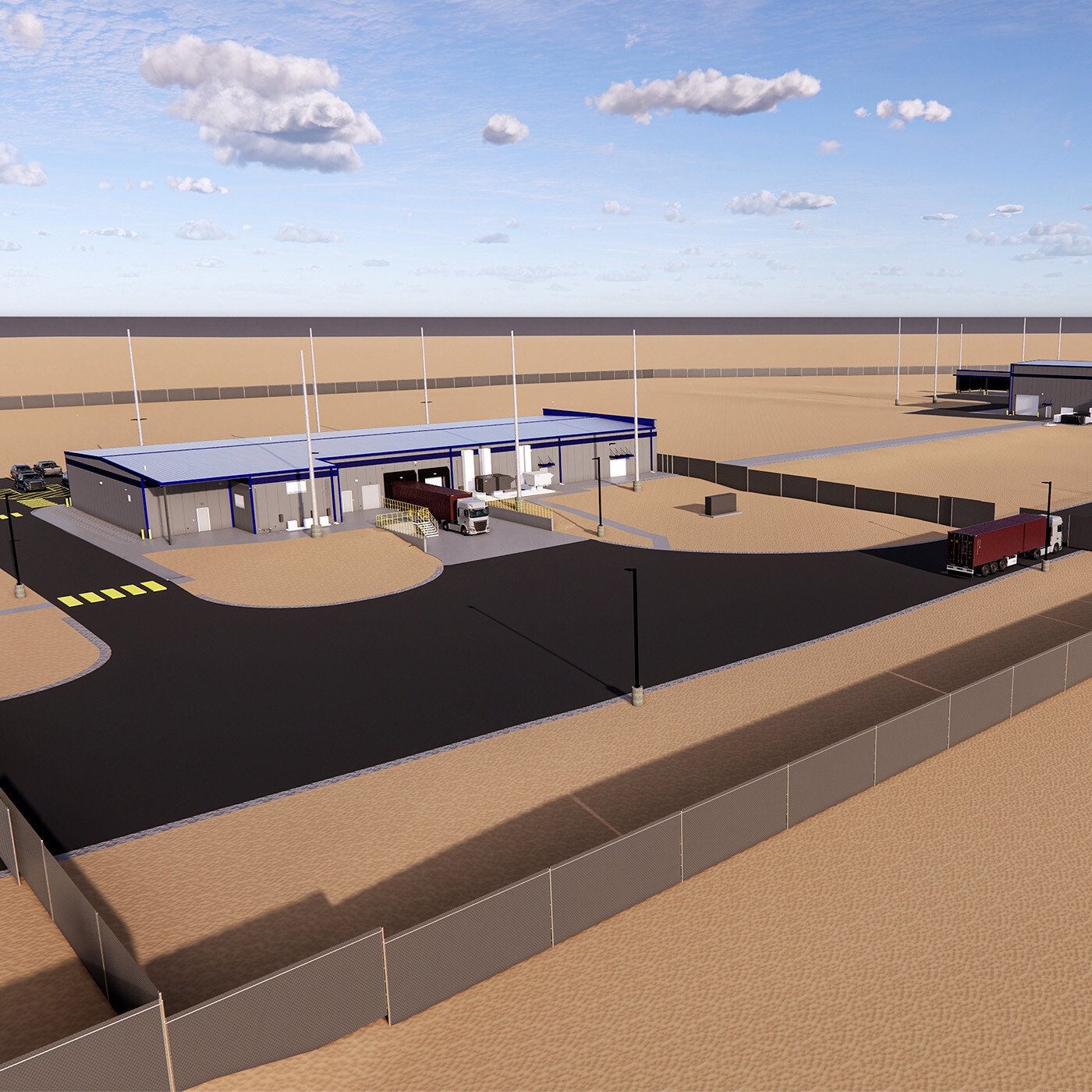

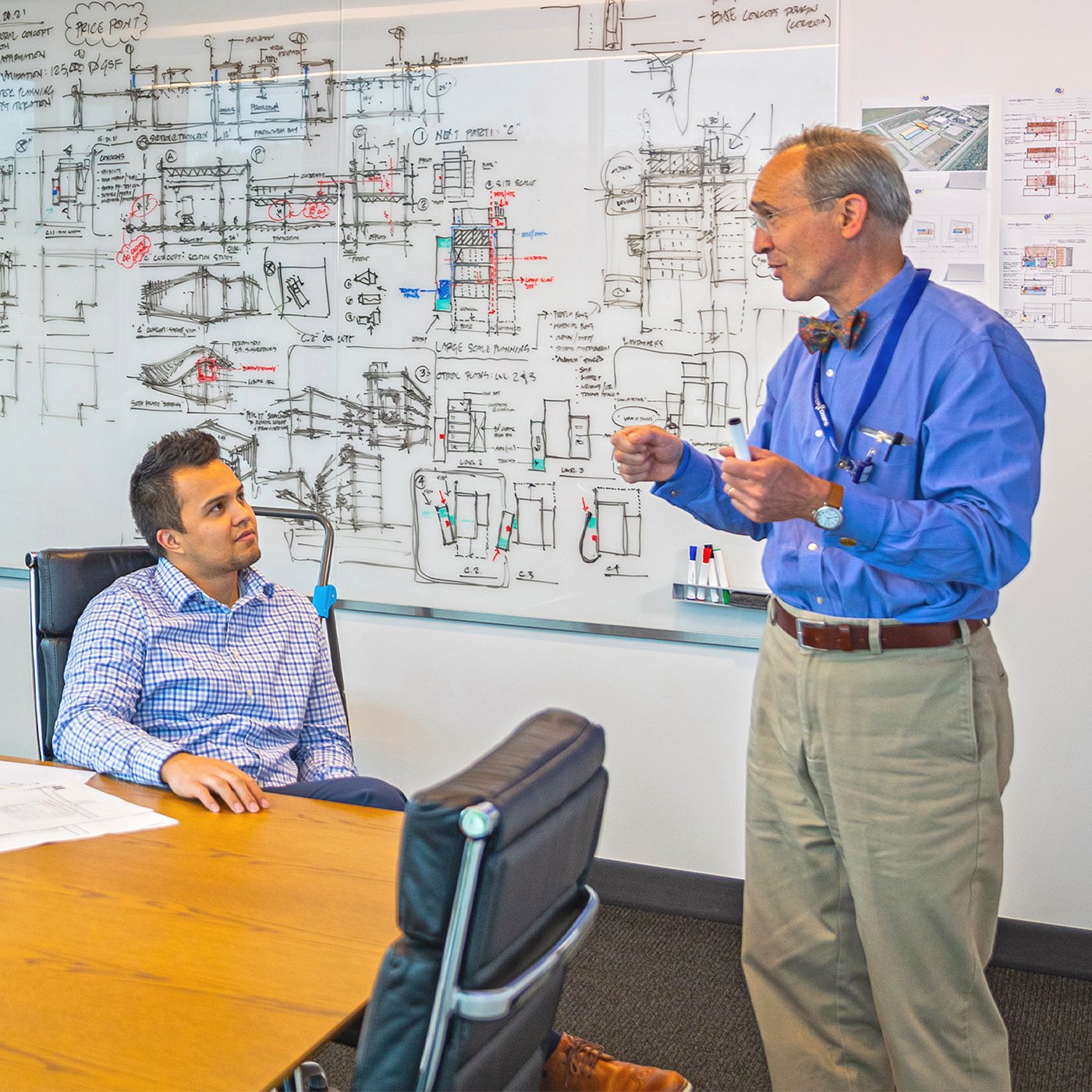

Manufacturing & Industrial

How Front-End Planning Cuts Costs and Speeds Up Project Delivery

(7)-Reporting-Deadline.jpg)